Our Quality

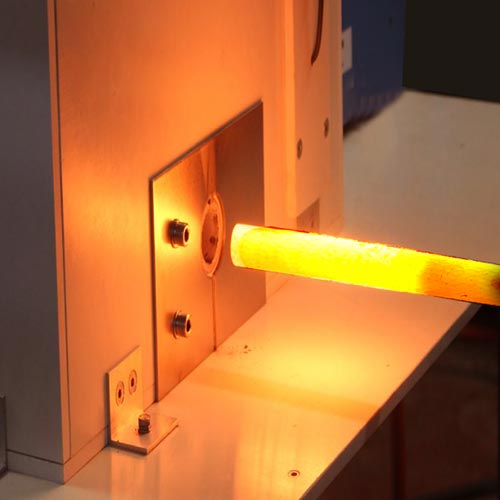

JK Forging have integrated high quality equipments, Advance Heating technology by induction long bar heating heater & Bar End. Bar heating machines built by power topology-based induction heater. Accessories of automatic feeder with chain conveyor, bar rejection system. Heavy duty & robust automatic loading system consisting of auto ramp loader, pneumatic bar lifting arrangement, motorized drive rollers with chain conveyor, pinch roller assembly, auto rejects mechanism for overheating reject bars, 3 way accept/reject system, non-contact infrared pyrometer.:

Induction Long Bar Heating System

- Advanced PLC control, power and temperature control

- Quick release connections for power and water

- Heavy-duty construction for tough forging conditions

- Bar end heaters with solenoid coil, multi stations, skid coil or choval coil for

- horizontal/vertical upsetting, swaging, thread rolling, piecing, and heading applications

- Automobile Industry Parts & Die

- Auto Component manufacturing

- Engineering Parts manufacturing

Application by

One stop solution for all Forge Ring requirement under one roof.

With 15 years experience and expertise in Forging process, ultimately help our customer for value for there money. J K Ring Forge manufacturer steel forge products as per the customer speciflcation in Automoble Industries Components Forged Steel Ring & Bushing, Close & Open Die Forgings We Very Well Blend Various Aspects of Technical Innovation, Bearing Races Ring Development of Infrastructure, carbon & alloy steel and supplies them in asforged, heat treated, and partially machined condition. are producing forged components up to 1kg weight. We Are Manufacture Diverse lndustrial ltem viz .

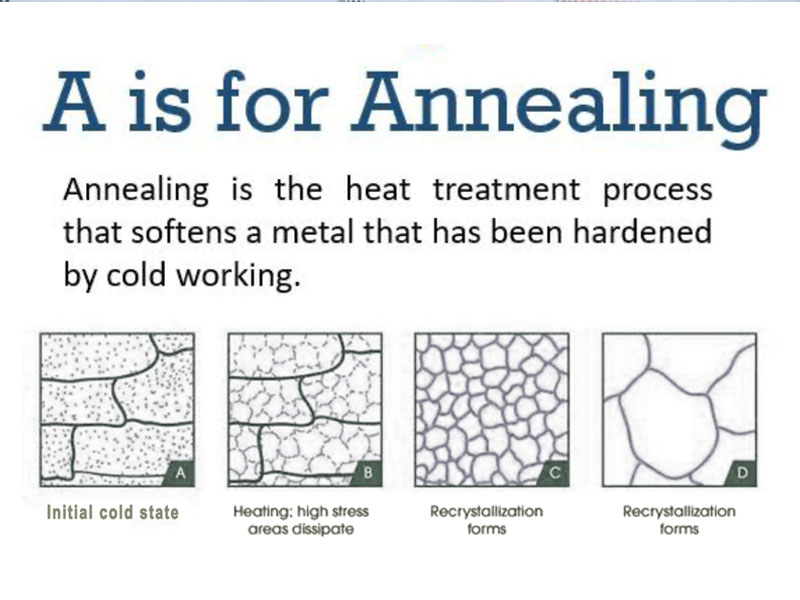

ANNEALING IS A HEAT TREATMENT

We believe in adapting to new technology keeping with the market trends. Our department knows that every little effort adds up to big success.

Annealing is a heat treatment in which a cold-worked or previously hardened metal is heated to a suitable temperature, soaked for an adequate time, and cooled at a controlled rate to reduce hardness, relieve internal stresses, improve ductility, and restore formability. In metallurgical terms, annealing lowers stored strain energy, rearranges/reduces dislocation density, and produces a softer, more uniform microstructure that is easier to machine, bend, draw, or deep-form.

Key Steps in Annealing:

Heating : The material is heated above its recrystallization temperature, allowing atoms to move and reorganize.

Soaking : Held at that temperature for a specific time to ensure uniform heating and structural changes.

Controlled Cooling : Cooled slowly, often within the furnace or in still air (for steel), to prevent new stresses from forming.

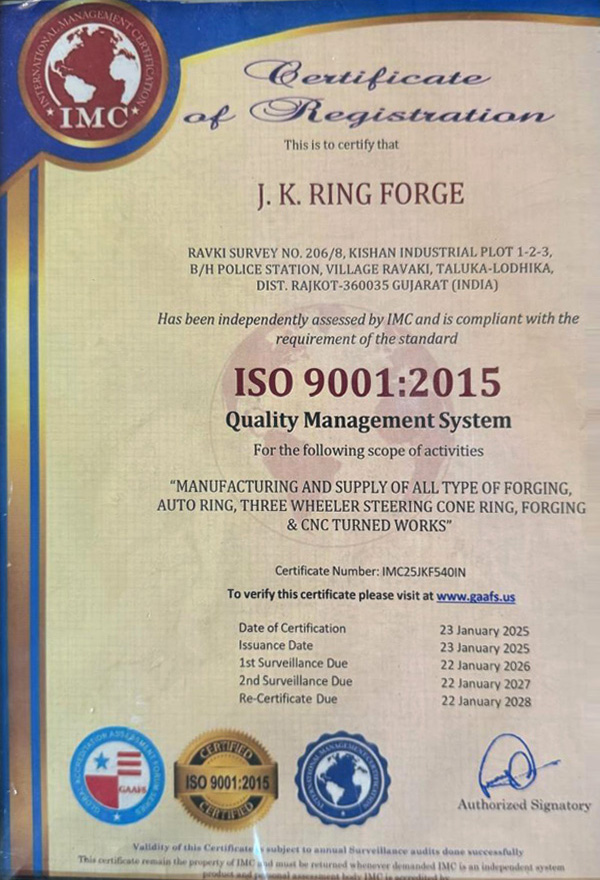

AN ISO 9001-2015

QUALITY CERTIFIED COMPANY

PRODUCTION

Automobile lndustries for Carbon Steel - Alloy Steel Structural Deferent Type Bearing & Bush of SS Forge Ring, Forged Bearing Races, Forged Bearing Inner-Outer Rings like Ball Bearings Manufacturer Suppliers Exporters Rajkot Gujarat India.

Manufacturing Capacity :

Round = 3omm to 9omm

Length = 45mm

Weight = 1oo gm to 1kg

QUALITY ASSURED

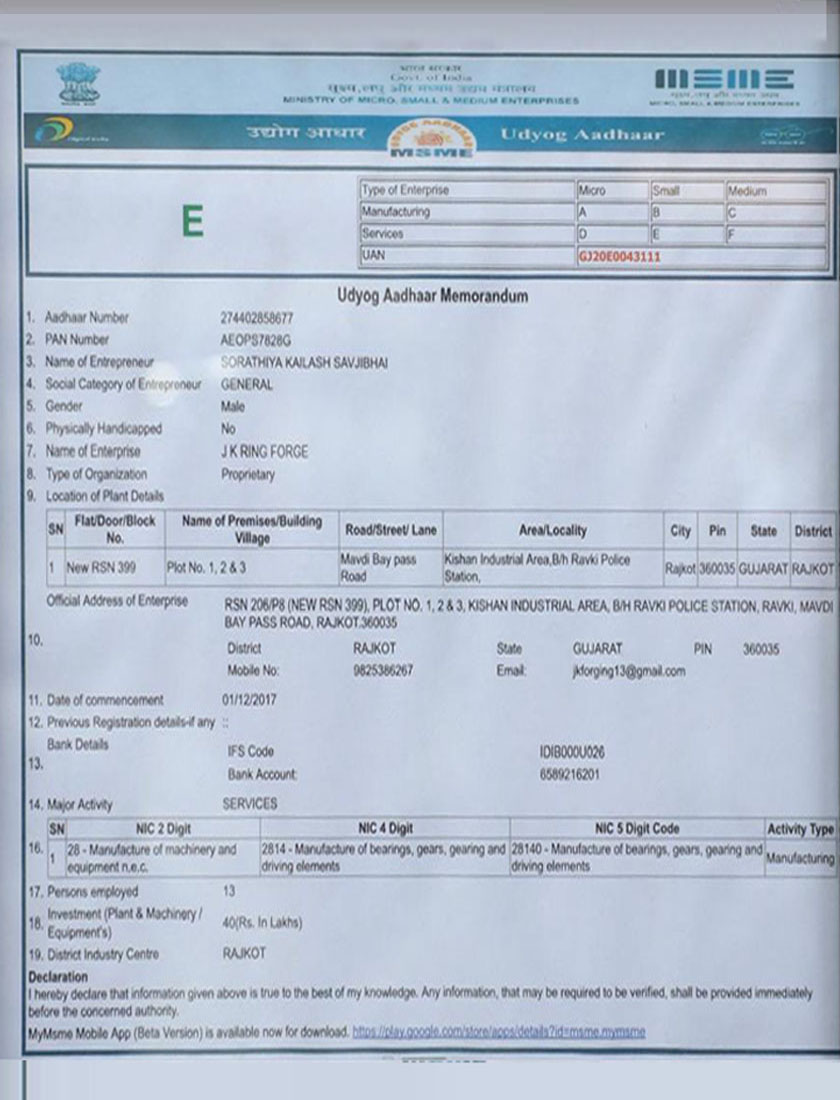

JK Ring Forge is managed by well qualified & experience professional Person, having last 11 years experience in forging unit. We are an ISO 9001-2015 quality accredited company by TUV Rheinland. JK STEEL FORGING We follow processes its own inspection plan for all the components and it’s process cycle at different stages of production. JK Ring Forge We are starts with understanding the Customers Requirement and continues till the customer is completely satisfied with the delivery of products and services. Quality Control procedures are well defined and thoroughly implemented. Forged SS Ring, Forged Bearing Races & Automotive Components built for result oriented work culture, to fulfill customer's needs in terms of Cost, Quality and Delivery. By enhancing effectiveness of people and plant equipment safely we are aiming towards zero losses. We also believe in continual improvement for effectiveness of Quality Management System through Team Work, Training and Focus on Actions and Results. We are continually improving our quality to serve our clients better.

We offer more possibilities to meet your every need.

RESEARCH & DEVLOMENT

The production and development of components is supported by a team of relevant field experienced hands to cover design and manufacturing even of complex products, own tools, selecting proper raw material, process controls, quality control, testing and inspection and many more…

The corefactors are:

- In-house Manufacturing Unit & Dexterous Workforce

- We To Guarantee World Class Stringent Quality Measures

- We Make The Best Use Of Available Resources

- We give Process Control & lmprovement

- We Do lnnovate And Execute New Raw Matertals

- We Use Fresh Techniques & Technologtes

- We Can Make Custom Based on Customers Drawings or Samples

WORK SHOP & LATEST MACHINERY

We believe in adapting to new technology keeping with the market trends. Our department knows that every little effort adds up to big success.

The corefactors are:

- Our entire human resource is will trained byour management in all technicalaspects.

- We provide clean, safe and green environment with industrial benchmark.

- We Use Fresh Techniques & Technologtes

- We Can Make Custom Based on Customers Drawings or Samples

Raw material that comes from the approved steel mills is reserved in the stockyard after 100% visual examination and sparktesting. Chemical, metallurgical and physical testing viz.. Upset test, step turn test, tensile test, impact test; macro etching along with metallurgical trusting of the material viz. Inclusion Rating and Microstructure are also carried out.

INCOMING MATERIAL INSPECTION

Raw material that comes from the approved steel mills is reserved in the stockyard after 100% visual examination and sparktesting. Chemical, metallurgical and physical testing viz.. Upset test, step turn test, tensile test, impact test; macro etching along with metallurgical trusting of the material viz. Inclusion Rating and Microstructure are also carried out. The material is approved in the laboratory and color code is given to each and every bar as the materialgrade followed by physical testing.

Raw material that comes from the approved steel mills is reserved in the stockyard after 100% visual examination and sparktesting. Chemical, metallurgical and physical testing viz.. Upset test, step turn test, tensile test, impact test; macro etching along with metallurgical trusting of the material viz. Inclusion Rating and Microstructure are also carried out.

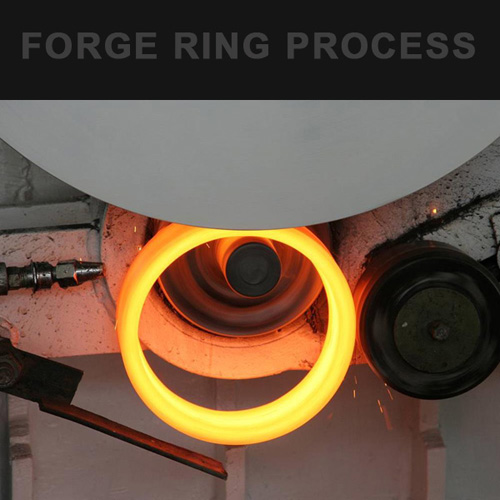

Auto Seamless SS Forge Ring & OPEN CLOSE FORGING DIE

Closed Die Forging

Closed Die Forging is a forging process in which dies move towards each other and covers the workpiece in whole or in part. The heated raw material, which is approximately the shape or size of the final forged part, is placed in the bottom die.

Open Die Forging

The Process of rolling seamless rings beings with open die forging which creates a perform workpiece. Open die forging processes, rounds

Auto Seamless SS Forge Ring

The Process of rolling seamless rings begins with open die forging which creates a perform workpiece. Open die forging proecesses, rounds,and upsets a piece of stock which aligns the grain flow of the metal. The workpiece is then punched in the center to create a hole necessary to place the workpiece in the ring mill.

Our Products Gallery

Forge Bearing Ring Manufacturer

SS Bearing Forged Rings Manufacturer

SS Rolled Ring Forging

Steel Ball Bearing Forge Outer Ring

Steel Automotive Forged Bushing

Forge Ring - Inner Outer Forged Bearing Ring

Steel Forged Bushing

Steel Forged Inner Outer Ring for Automobile

Steel Forged Tapper Roller Inner Ring

Steel Forged Tapper Roller Outer Ring

Steel Forged Flange Ring - Auto Parts Ring

SS Bearing Races Ring Forged

Forge Ring Manufacturer - Foundry - Industries

SS Forged Bearing Ring

Steel Rod Bar Heavy